Linear guide systems are essential components in industrial automation, providing accurate linear motion for a broad range of applications. These systems consist of rails and carriage units designed to minimize friction and guarantee consistent operation. By optimizing the design and implementation of linear guide systems, manufacturers can significantly improve the precision of their industrial processes.

This refinement can lead to enhanced product quality, reduced downtime, and minimized operational costs. Numerous factors affect the precision of linear guide systems, including the type of rails used, the lubrication system, the load capacity, and the environmental conditions.

Through careful selection and deployment of components, manufacturers can maximize the performance of their linear guide systems and achieve the desired level of precision for their unique automation needs.

Understanding Linear Rail Sizes: A Comprehensive Guide

Linear rails guide precise linear motion in machinery and equipment. To determine the appropriate linear rail size for your application, it's crucial to grasp the various sizing factors involved. These factors encompass rail dimension, width, and height. Additionally, consider the load Linear rail guide capacity required, as this will affect the necessary rail size.

A properly sized linear rail ensures smooth, efficient, and consistent motion.

Enhancing Efficiency with Linear Guide Rails

Linear guide rails deliver a robust method for achieving high-precision linear motion. Their aligned design reduces friction and wear, ensuring smooth and efficient operation. This produces in increased productivity by optimizing the speed and accuracy of your equipment. Furthermore, linear guide rails feature a minimal design, making them suitable for a broad range of applications in fields such as robotics.

By utilizing linear guide rails into your designs, you can significantly enhance efficiency and complete performance.

Benefits of Linear Rail Guides for Motion Control

Linear rail guides are widely selected for motion control applications due to their high accuracy and load capacity. These guides offer a smooth and linear path of travel which is essential for precise control in various industrial machinery. Compared to other guiding systems, linear rail guides demonstrate exceptional resistance to wear thanks to their strong frame. This reduces downtime, contributing to overall optimized performance.

- In addition, linear rail guides offer excellent rigidity, ensuring that the motion is precise. This is particularly beneficial for applications requiring high payloads.

- {Lastly, linear rail guides areknown for their versatility, making them a suitable choice for a wide range of motion control applications in industries such as automotive, robotics, and manufacturing.

Linear Guide Rails vs. Motion Components: Identifying the Best Fit

In the realm of precise motion control, ball screws stand as fundamental elements. Each offers unique advantages, making the choice a critical one based on specific application requirements. Linear guide rails excel in situations demanding high payload tolerance, providing smooth and reliable movement. Conversely, ball screws shine when fine-tuned placement is paramount. Their inherent design allows for minimal resistance, resulting in high repeatability. To make an informed selection, consider the type of your project, analyzing factors such as weight capacity, velocity needs, and the degree of accuracy demanded.

Precision Engineering: Delving into the World of Linear Guide Systems Exploring Precision Engineering: The Realm of Linear Guide Systems Linear Guide Systems in Precision Engineering: A Deep Dive

Precision engineering demands unparalleled accuracy and control, pushing the boundaries of mechanical design. Within this realm, linear guide systems emerge as critical components, enabling smooth, frictionless motion along straight paths. These sophisticated assemblies comprise a set of precisely machined rails or guides and carriage blocks, working in synergy to facilitate accurate positioning and movement.

Linear guide systems are meticulously engineered to minimize backlash, vibration, and wear, ensuring consistent performance even under demanding operational conditions. The choice of materials plays a pivotal role in determining their load capacity, rigidity, and environmental resistance. Commonly employed materials include steel alloys, hardened chrome-plated surfaces, and self-lubricating polymers.

- Accurate linear motion is paramount in various industries, including automation, robotics, medical devices, and semiconductor manufacturing.

- This technology facilitate the precise positioning of components, enabling intricate tasks like assembly, cutting, or testing.

- Understanding the diverse types of linear guide systems, their performance parameters, and appropriate selection criteria is essential for optimizing machine design and achieving desired operational outcomes.

Edward Furlong Then & Now!

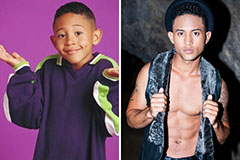

Edward Furlong Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now!